Article by Teun Schröder for Change Inc.

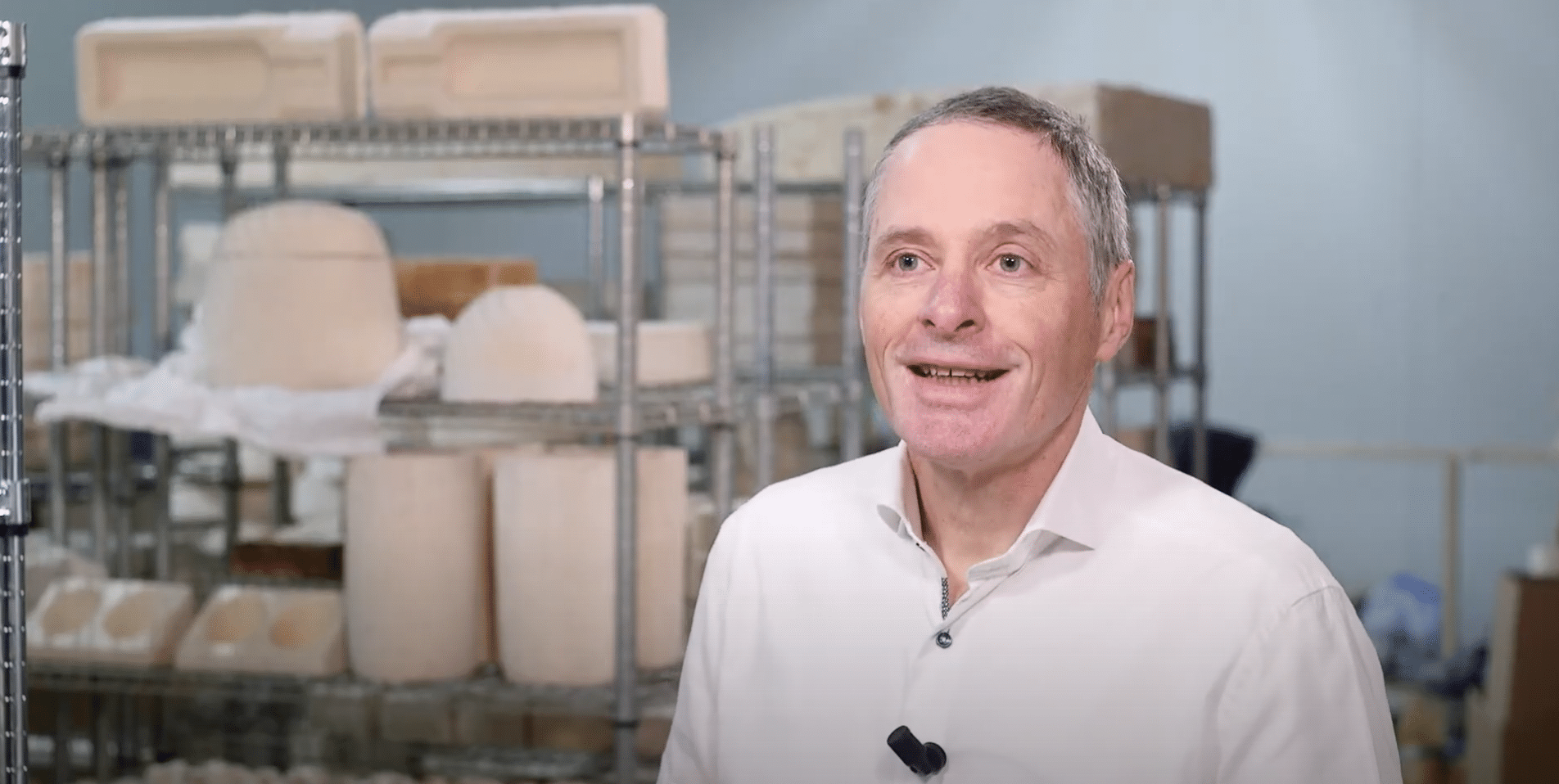

Jan Berbee became “infected with the packaging virus” during his career. As a consultant for sustainable packaging, he helped companies reduce their use of tape, plastic and boxes until he encountered a mushroom farmer looking for an alternative to the blue plastic trays. Berbee said, “That’s when I discovered Mushroom® Packaging.”

First, a step back to the basics. Under the cap of a mushroom are spores. These spores can become detached and land in the ground through the wind. Such a spore secretes enzymes in the form of threads that grow into the soil. The result is a network of fungi that can cover an area of several square kilometers. This network of fungal threads is called mycelium. You could write a book about the wondrous world of mycelium in nature (or watch the Netflix documentary Fantastic Fungi).

Mycelium Packaging

Berbee was enchanted when he learned that two American students were using mycelium for packaging as an alternative to Styrofoam. “They already had patents, so we immediately went into licensing negotiations.” Not long after, Berbee founded his own mycelium company, Grown bio. “A few months later, we were able to start growing mycelium in the shed at my home.”

Growth forms and Fungi

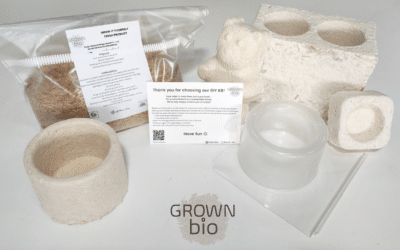

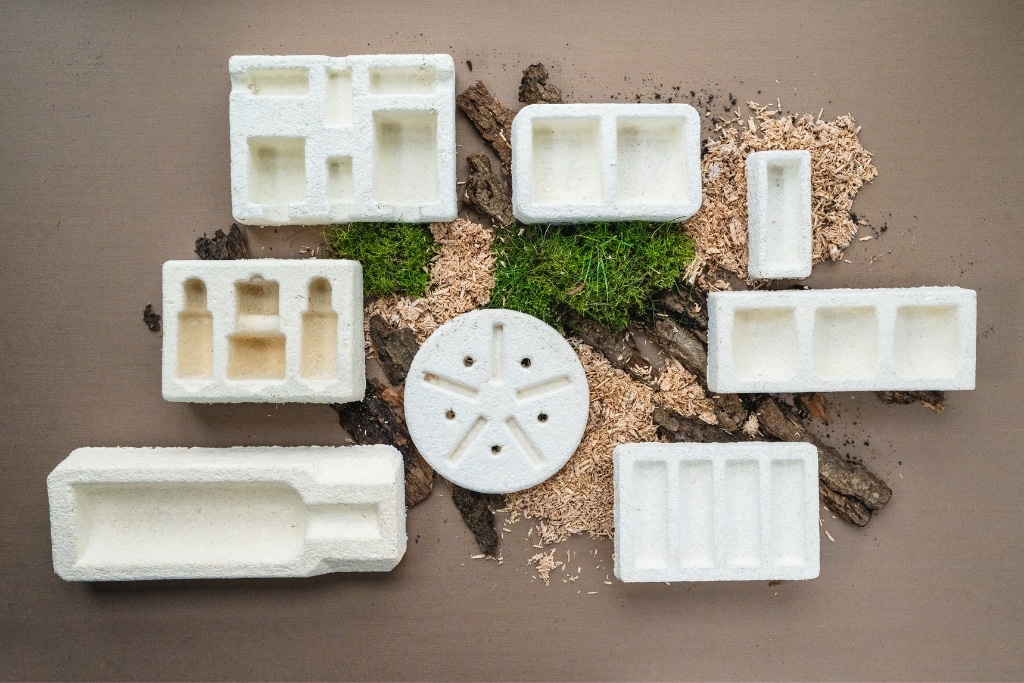

Growing mycelium works like this: “You start by designing a packaging shape on the computer,” says Berbee. “From that shape, you make a plastic growth form. We do that from recycled PET. The growth form is then filled with substrate, a mixture of mycelium and fibrous agricultural residues, which feeds the mycelium. In five to six days, the substrate grows into the shape of the growth form at a temperature of 25 degrees. After that, you have a living fungus in the shape of the packaging. This fungus is still 50 percent water. In the last step of the process, we put the product in the oven at a temperature of 80 degrees. This kills the fungus, stops the growth, and evaporates the water. The result is a hardened biobased packaging shape.” A large part of the work is waiting for the fungus to grow. “On Fridays, we fill the molds. On Tuesday, we do a quick check to see if anything unusual is happening, and on Thursday, we come back to put the products in the oven.”

Properties of Mycelium Packaging

According to Berbee, there are many advantages to mycelium packaging, besides being a petroleum-free material as an alternative to Styrofoam. “The substrate consists of mycelium in addition to agricultural residues. We use hemp from Groningen or straw from rabbit hutches. In Spain, we managed to use the chaff from paella rice as food for the fungus. And we did the same with the cuttings from a champagne house.” The fungus is also non-flammable, has good insulation values, and is moisture-resistant to a certain extent. “We also have a project where our packaging is used in the fish industry,” says Berbee. “The packaging contains fish, ice and water. It stays good for at least a week, long enough for the duration of transport.”

Compostable

And after use, the mycelium packaging simply composts in nature. “In the winter months, it takes six to seven weeks, just in my own garden. In the summer, when it’s warmer and more humid, it goes a bit faster. The packaging can also be included in the paper recycling stream.” But actually, Berbee prefers higher-quality applications where the packaging remains intact. “Like a pen holder or as a compostable flowerpot.”

Biobased Building

The versatile advantages of mycelium also make the material suitable for use in construction, such as for wall panels and insulation. However, Grown.bio recently decided to focus solely on packaging material. “Primarily because we can make a huge impact if we help eliminate Styrofoam from the world. The construction sector is, of course, massive. But the disadvantage is that each country has different certifications that construction material must meet. And the certification process is time-consuming and expensive. But construction remains, certainly for the future, an interesting market.”

New Factory

In the coming years, Berbee wants to grow Grown bio larger. His factory currently produces 300,000 packages per year. But he already has plans for a new factory with a capacity of 10 million to be opened in 2025. For this, he is still looking for investors. “The most fun is if this is a strategic financier, someone who knows the packaging industry well.”

“We’re currently focusing mainly on the luxury segment, like perfumes and champagne,” Berbee continues. “Our packaging material is still more expensive than Styrofoam. So it’s especially interesting for customers who believe in our story, have sustainability ambitions.

Thanks for the Interview, Teun!