How mycelium helps to reduce CO2 emissions

CO2 capturing

We all know that climate change is a pressing global issue that demands our immediate attention. The Intergovernmental Panel on Climate Change has proven that climate change and its dramatic consequences are the result of the higher percentage of Green House Gases (GHG) in the air (source). It is crucial for us to act and reduce GHC emissions to decrease the impacts of climate change. That’s why we believe that more products should be bio-based. A good example is the use of organic fibers such as hemp or cattail or reed. These crops absorb CO2 while they grow. This is called Photosynthesis: the process by which plants use sunlight, water, and carbon dioxide to create oxygen, fibers and other (good) stuff.

CO2 Capturing with Mycelium products

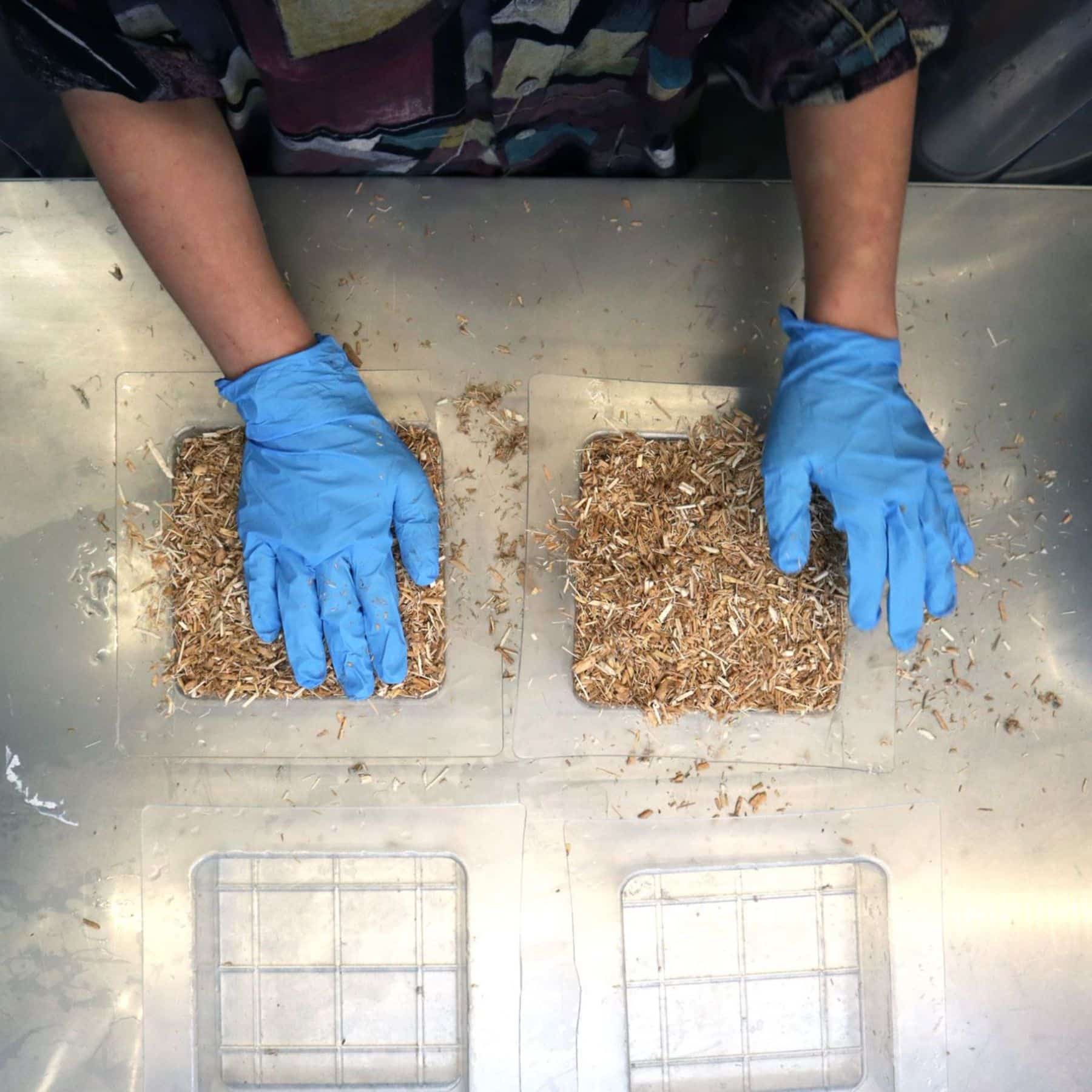

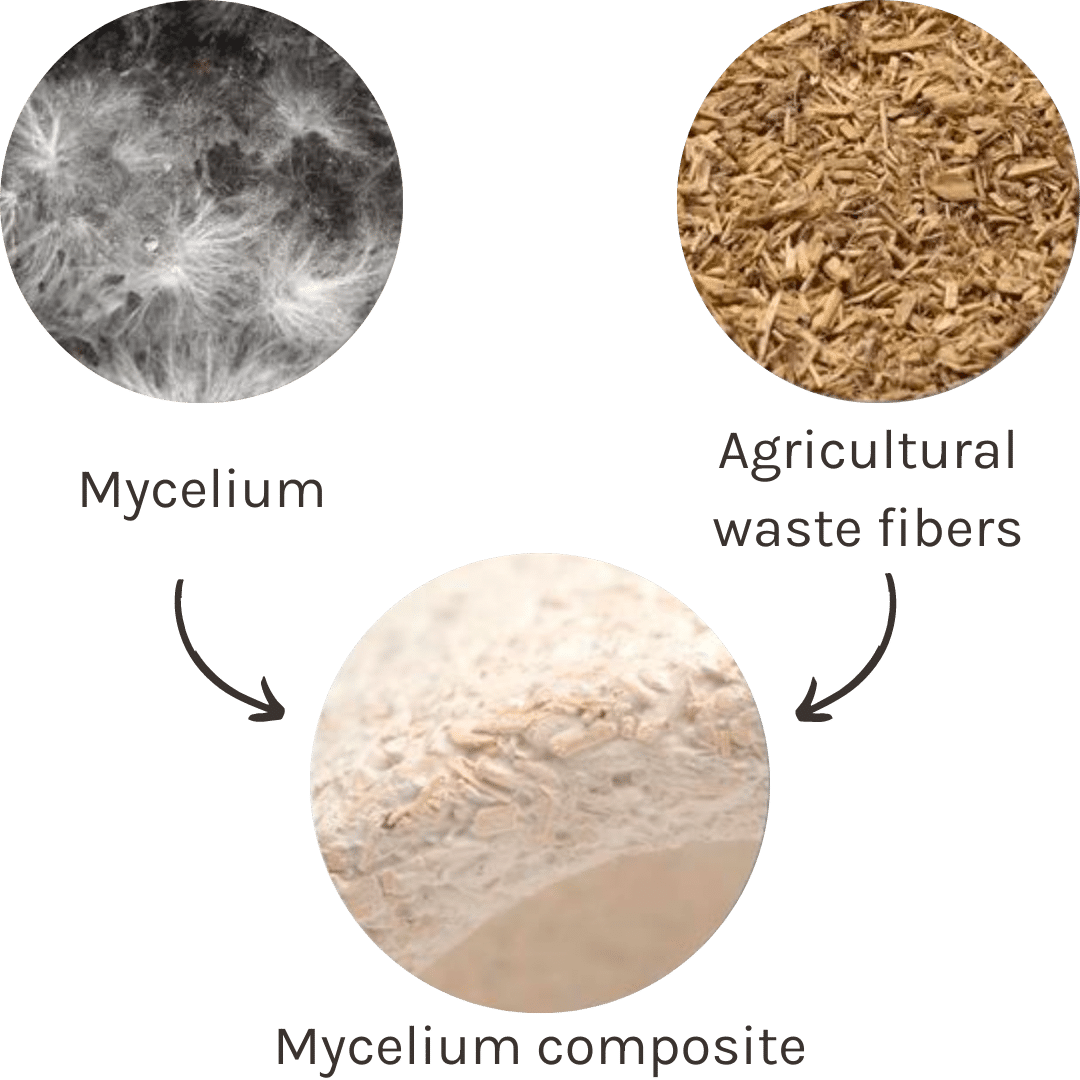

One of the ways we can make a difference is through our innovative use of mycelium based products. For that we only need mycelium, the root structure of fungi and local agricultural waste, we use mostly hemp waste but other waste streams can also be used.

Did you know that hemp captures the most CO2 per square acre of almost all crops while growing? And it makes its own anti-bug stuff, but only if it gets attacked. Very efficient!

All this makes hemp a valuable resource for capturing and storing carbon dioxide.

When we say that a mycelium product is CO2 negative, we mean that a significant part of the captured CO2 (in the case of hemp) can still be considered in the mycelium product when it leaves our factory.

A significant part? Yes, because the steps from harvesting the waste fibers, to making substrate and growing products in growth forms, all cause CO2 emissions.

So, except for the hemp that has captured CO2, all steps that are needed to grow mycelium products actually emit CO2. However, the balance is still in favour of the mycelium composite.

Let’s go to some numbers now. It is not easy to give exact numbers and getting them is very expensive. Also, mycelium specific numbers alone don’t tell the story, a comparison does. We offer the alternative to Expanded Polystyrene (EPS), also known as Styrofoam for example.

We have calculated a comparison using the CIF-method developed and validated by the Climate Impact Forecast organization. It calculates the difference in CO2 equivalent of mycelium composite over EPS. Wait what CO2 equivalent? Yes, we told you it’s not going to be easy. When talking about the impact of a material or process, we need to look at the Global Warming Potential (GWP) of the material or process. Just like the costs of something is expressed in a unit (€, $ or …) the GWP is expressed in kg CO2 equivalent or kg CO2-eq in short. The GWP of 1 kg of CO2 is 1kg CO2-eq, but some gases used in making foams (like EPS) have a GWP (source) ranging from 5-1300 CO2-eq. Which means that also a small amount can already have a big warming effect. These effects are making the calculation of the impact quite an exercise.

Carbon footprint

CO2 eq.

-0.5243 kg / L of packaging

Of course, after composting the mycelium material, the CO2 that was captured by the hemp is released again into the atmosphere. That is one reason why we actively promote re-use of our mycelium packaging! Let’s keep the carbon captured!

To further improve the balance of CO2 we carefully consider the carbon footprint throughout our production process. By optimizing each step, from harvesting, cutting, and mixing it with mycelium to creating growth forms, growing, and drying, we minimize CO2 emissions to the best of our ability. For instance, we engineered and built some very efficient drying chambers by ourselves.

Calculated per L of packaging, the mycelium alternative saves ~600gr CO2 per L of packaging compared to our main rival EPS.

Besides Global Warming, there’s also (eco)toxicity, fresh water usage, ozone depletion and other problems that EPS has over our mycelium composite.

Mycelium saves…

600

grams CO2

per L of packaging

compared to our main rival EPS

Our mission is to offer a 100% natural alternative and only use renewable resources because it’s a fact that EPS is all fossil fuel-based, which means that:

- Once it is created, the fossil sources are gone forever. Forever? Yes, it has taken millions of years to create fossil fuels. Once they are consumed we can never get them back.

- And, the location where the fossil sources are won, is usually far away.

Going Local

It is not only the bio-based waste stream that makes mycelium composite such a favourable product. As said, Grown bio is also taking actions to further reduce the footprint of all activities in their production plant. Examples are that we have eliminated the use of gas for heating, started using heat recovery and using green electricity. But there is a third element that helps to keep the CO2 impact as low as possible: that is to produce as locally as possible. Shipping a light product like mycelium composites, just like EPS, unfortunately does emit CO2. So, the shorter the distance to our customer, the better it is. That is why Grown bio plans not to have a few very large factories, but multiple smaller ones, closer to their customers.

This of course comes with a challenge: with several smaller factories it a bigger challenge to create cost reductions than with one big one. Nevertheless, we are relentless in our pursuit of cost reduction so we can maintain our strategy of ‘going local’.

And lastly, one final word about going local: being local also creates opportunities to use the waste streams that are present in that specific geographical area. For example: hemp waste in the Netherlands. Winery waste in France. Or rice waste in Spain.